Introduction to Bubble Wrap

Bubble wrap is a widely used packaging material known for its cushioning properties. It consists of a sheet of plastic with regularly spaced, protruding air-filled bubbles. This design provides a protective layer that absorbs shock and prevents damage to fragile items during shipping and handling. The creation of bubble wrap involves a fascinating process that combines material science and manufacturing technology.

The History of Bubble Wrap

Bubble wrap was invented in 1957 by Alfred Fielding and Marc Chavannes, who initially intended to create a new type of textured wallpaper. However, the product did not succeed in the wallpaper market. Instead, they discovered its potential as a packaging material, and in 1960, they founded Sealed Air Corporation to market bubble wrap as a protective packaging solution.

Materials Used in Bubble Wrap Production

The primary material used in bubble wrap is polyethylene, a type of plastic known for its flexibility, durability, and resistance to moisture. Polyethylene is available in various forms, but low-density polyethylene (LDPE) is typically used for bubble wrap due to its ability to form thin, pliable films. The production process may also involve additives to enhance the material’s properties, such as UV inhibitors to prevent degradation from sunlight exposure.

The Manufacturing Process of Bubble Wrap

Extrusion

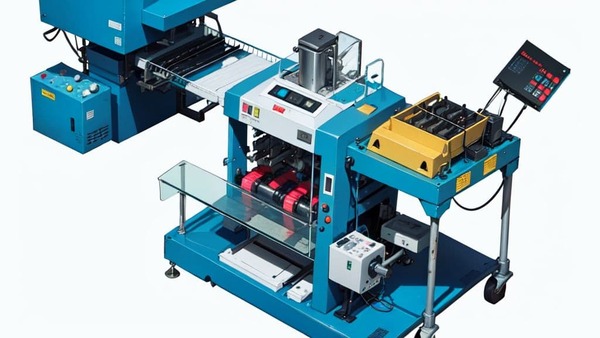

The manufacturing process begins with the extrusion of polyethylene resin pellets. These pellets are fed into an extruder, a machine that heats and melts the plastic. The molten plastic is then forced through a die to form a thin film. This film serves as the base layer for the bubble wrap.

Bubble Formation

The next step involves creating the air bubbles. The thin film is passed over a drum with evenly spaced holes. A vacuum is applied from inside the drum, pulling the film into the holes and forming the bubble shapes. As the film cools, the bubbles solidify, retaining their shape.

Lamination

To complete the bubble wrap, a second layer of film is laminated onto the bubble side. This layer seals the bubbles, trapping air inside and providing the cushioning effect. The lamination process involves heat and pressure to ensure a strong bond between the two layers.

Cutting and Winding

Once the bubble wrap is formed, it is cut into desired widths and lengths. The finished product is then wound onto rolls for easy storage and transportation. The rolls can be customized to meet specific customer requirements, such as different bubble sizes or perforations for easy tearing.

Quality Control in Bubble Wrap Production

Quality control is a critical aspect of bubble wrap production. Manufacturers must ensure that the bubbles are uniform in size and properly sealed to maintain their protective properties. Regular inspections and testing are conducted throughout the production process to identify and rectify any defects. This includes checking for consistent film thickness, bubble integrity, and overall product durability.

Environmental Considerations

As with many plastic products, bubble wrap raises environmental concerns due to its non-biodegradable nature. However, efforts are being made to address these issues. Some manufacturers offer bubble wrap made from recycled materials or biodegradable alternatives. Additionally, recycling programs are available in some areas to reduce the environmental impact of bubble wrap disposal.

Applications of Bubble Wrap

Bubble wrap is used in various industries for packaging and protection. Its primary application is in shipping and logistics, where it protects fragile items such as electronics, glassware, and artwork. It is also used in the automotive industry to protect parts during transportation and in the construction industry for insulation purposes. Additionally, bubble wrap is popular in the retail sector for packaging consumer goods.

Conclusion

Bubble wrap is a versatile and effective packaging material that has become an essential part of modern logistics and shipping. Its production involves a series of well-coordinated steps, from extrusion to lamination, ensuring that the final product provides the necessary protection for a wide range of items. While environmental concerns persist, advancements in recycling and biodegradable materials offer promising solutions for the future of bubble wrap.