Understanding the Principle of Packaging Machines

Packaging machines play a crucial role in various industries, including food and beverage, pharmaceuticals, and consumer goods. They are designed to automate the process of packaging products, ensuring efficiency, consistency, and quality. Understanding the principles behind these machines can help businesses optimize their packaging processes and select the right equipment for their needs.

Basic Principles of Packaging Machines

Packaging machines operate based on several fundamental principles, which can vary depending on the type of machine and the specific application. However, some core principles are common across most packaging equipment:

Automation and Efficiency

One of the primary principles of packaging machines is automation. These machines are designed to automate repetitive tasks that would otherwise require manual labor. By automating the packaging process, businesses can increase efficiency, reduce labor costs, and minimize human error. Automation also allows for faster production speeds, enabling companies to meet high demand and maintain consistent output.

Consistency and Quality Control

Consistency is a critical aspect of packaging, as it ensures that each product is packaged uniformly, maintaining brand integrity and customer satisfaction. Packaging machines are equipped with precise controls and sensors to ensure that each package is filled, sealed, and labeled consistently. This level of precision helps maintain quality control, reducing the risk of defects and ensuring that products meet industry standards.

Flexibility and Adaptability

Modern packaging machines are designed to be flexible and adaptable to different products and packaging materials. This flexibility allows businesses to switch between different packaging formats and sizes with minimal downtime. Many machines come with adjustable settings and interchangeable parts, enabling them to handle a wide range of products, from liquids and powders to solids and semi-solids.

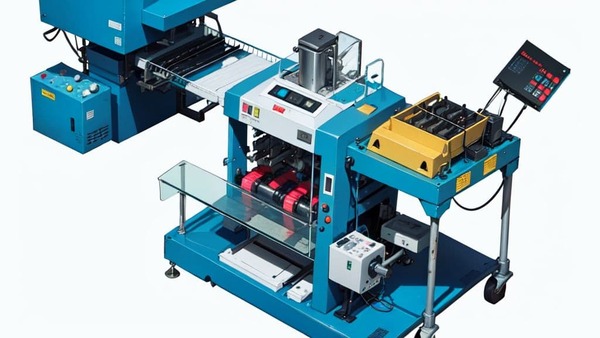

Integration with Other Systems

Packaging machines are often integrated with other systems within a production line, such as filling machines, labeling machines, and conveyors. This integration ensures a seamless flow of products through the packaging process, reducing bottlenecks and improving overall efficiency. Advanced packaging systems may also be integrated with data management systems, allowing for real-time monitoring and control of the packaging process.

Types of Packaging Machines

There are several types of packaging machines, each designed for specific applications and packaging formats. Understanding the different types of machines can help businesses choose the right equipment for their needs:

Filling Machines

Filling machines are used to fill containers with a specific amount of product. They are commonly used in the food and beverage industry for filling bottles, cans, and jars with liquids, powders, or granules. Filling machines can be classified into several types, including volumetric fillers, gravimetric fillers, and auger fillers, each suited for different types of products and packaging requirements.

Sealing Machines

Sealing machines are used to seal packages, ensuring that the contents are protected from contamination and leakage. These machines can handle various sealing methods, such as heat sealing, ultrasonic sealing, and adhesive sealing. Sealing machines are essential for maintaining product freshness and extending shelf life, particularly in the food and pharmaceutical industries.

Labeling Machines

Labeling machines are used to apply labels to packages, providing important information such as product name, ingredients, and expiration date. These machines can handle various label types, including pressure-sensitive labels, shrink sleeves, and wrap-around labels. Labeling machines are crucial for ensuring compliance with industry regulations and enhancing brand visibility.

Wrapping Machines

Wrapping machines are used to wrap products in protective materials, such as plastic film or paper. These machines are commonly used for packaging items like baked goods, candies, and consumer electronics. Wrapping machines can be classified into several types, including flow wrappers, shrink wrappers, and stretch wrappers, each suited for different packaging needs.

Conclusion

The principle of packaging machines revolves around automation, consistency, flexibility, and integration. By understanding these principles, businesses can optimize their packaging processes, improve efficiency, and maintain high-quality standards. With a wide range of packaging machines available, companies can choose the right equipment to meet their specific needs and enhance their production capabilities.