Introduction to Strip Packaging in Pharmacy

Strip packaging is a method used in the pharmaceutical industry to package medications in a way that ensures their safety, integrity, and efficacy. This packaging method involves sealing individual doses of medication between layers of foil or plastic, creating a strip of sealed units. Each unit typically contains a single dose of medication, making it convenient for patients to take the correct dosage at the right time. Strip packaging is particularly popular for solid dosage forms such as tablets and capsules.

Benefits of Strip Packaging

Strip packaging offers several advantages over traditional bulk packaging methods. Firstly, it enhances patient compliance by providing a clear and organized way to take medications. Patients can easily track their dosage regimen, reducing the risk of missed or double doses. Secondly, strip packaging protects the medication from environmental factors such as moisture, light, and air, which can degrade the active ingredients. This protection extends the shelf life of the medication and ensures that patients receive the full therapeutic benefit.

Additionally, strip packaging is tamper-evident, providing an extra layer of security against contamination or counterfeiting. Each dose is individually sealed, making it immediately apparent if the packaging has been compromised. This feature is particularly important for medications that are sensitive to tampering or require strict control, such as controlled substances.

Strip Packaging Process

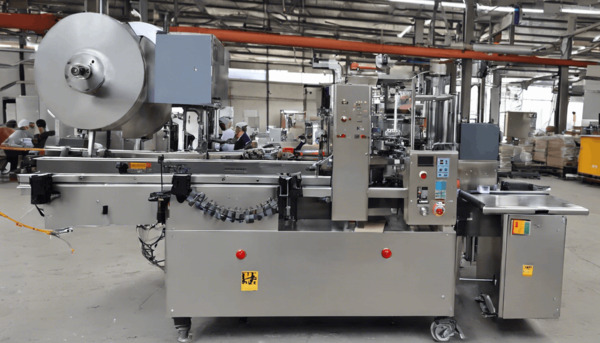

The strip packaging process involves several key steps to ensure that the medication is packaged safely and efficiently. The process begins with the preparation of the medication, which is typically in the form of tablets or capsules. These are fed into a strip packaging machine, which is equipped with a feeding system to ensure accurate dosing.

The machine then aligns the medication with the packaging material, which is usually a combination of foil and plastic. The material is fed into the machine in rolls, and the medication is placed between two layers. The machine uses heat and pressure to seal the layers together, creating individual pockets for each dose. The sealed strip is then cut to the desired length and packaged for distribution.

Applications and Considerations

Strip packaging is widely used for a variety of medications, including over-the-counter drugs, prescription medications, and nutraceuticals. It is particularly beneficial for medications that require precise dosing or are taken on a regular schedule. Strip packaging is also used in clinical trials to ensure that participants receive the correct dosage and to facilitate adherence to the study protocol.

When implementing strip packaging, pharmaceutical companies must consider several factors, including the type of medication, the required dosage form, and the intended use. The packaging material must be compatible with the medication to prevent interactions that could affect stability or efficacy. Additionally, the packaging process must comply with regulatory standards to ensure the safety and quality of the medication.

Challenges and Future Trends

Despite its advantages, strip packaging also presents certain challenges. The initial setup cost for strip packaging machinery can be high, and the process requires precise control to ensure consistent quality. Additionally, the packaging material must be carefully selected to provide adequate protection without compromising the medication’s accessibility.

Looking to the future, advancements in strip packaging technology are expected to further enhance its benefits. Innovations such as smart packaging, which incorporates sensors or electronic components, could provide real-time monitoring of medication conditions and improve patient adherence. Sustainable packaging materials are also being developed to reduce the environmental impact of strip packaging.

Conclusion

Strip packaging is a valuable method in the pharmaceutical industry, offering benefits in terms of patient compliance, medication protection, and security. While there are challenges to its implementation, ongoing advancements in technology and materials are likely to address these issues and expand the applications of strip packaging in the future. As the industry continues to evolve, strip packaging will remain an important tool for ensuring the safe and effective delivery of medications to patients.