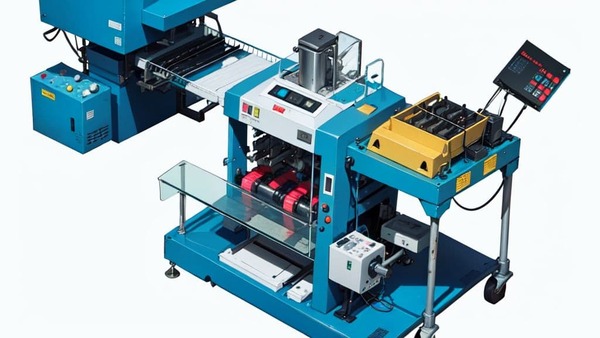

Introduction to Automatic Strip Packing Machines

Automatic strip packing machines are critical components in the packaging industry, especially for pharmaceutical, food, and consumer goods sectors. These machines are specifically designed to pack items like tablets, capsules, food products, and other similar materials into airtight, durable strips or pouches. By automating the process, these machines enhance efficiency, reduce material wastage, and maintain consistency in packaging quality.

In this comprehensive article, we will delve deep into the intricacies of automatic strip packing machines, their working principles, types, advantages, key components, and industry applications. Additionally, we will discuss factors to consider when selecting an automatic strip packing machine and explore emerging trends in the technology. Whether you are a packaging professional or someone new to the industry, this guide will provide a thorough understanding of this essential equipment.

What is an Automatic Strip Packing Machine?

An automatic strip packing machine is a type of packaging equipment that forms sealed pouches or strips containing products. These machines use heat-sealing technology to encase the product between layers of flexible packaging material such as aluminum foil, plastic films, or laminates. The primary purpose is to protect the product from environmental factors like moisture, air, and contamination while maintaining its integrity during storage and transportation.

Typically, these machines are fully automated, meaning they perform all the tasks involved in the packaging process—from feeding the product to sealing and cutting the strips—without manual intervention. This level of automation makes them ideal for industries where speed, accuracy, and hygiene are paramount.

Working Principle of Automatic Strip Packing Machines

Automatic strip packing machines operate based on a series of synchronized steps that transform raw materials into finished packaged products. Below is an overview of the working principle:

1. Feeding the Product

The process begins with feeding the product (e.g., tablets or capsules) into the machine’s hopper or feeding system. Advanced machines often include vibratory or rotary feeders to ensure that each product is properly aligned before entering the packaging section.

2. Unwinding Packaging Material

Rolls of flexible packaging material are mounted onto unwinding systems within the machine. The material is fed through rollers that keep it taut and aligned as it moves towards the sealing section.

3. Forming Pockets or Cavities

If required by the design, cavities or pockets are formed on the packaging material using dies or molds. These cavities act as receptacles for the product.

4. Product Placement

The product is placed into the formed cavities using automated systems like pick-and-place mechanisms or gravity feeders. This step is critical to ensure accuracy and prevent misalignment.

5. Sealing and Cutting

Heat-sealing units apply pressure and heat to seal the packaging material around the product, creating airtight strips or pouches. After sealing, the strips are cut into individual units or batches based on pre-set configurations.

6. Discharge and Collection

Finally, the completed strips are discharged from the machine and collected for further processing like labeling or boxing.

Types of Automatic Strip Packing Machines

Automatic strip packing machines come in various configurations designed to meet different packaging needs. Below are some of the most common types:

1. Flat Plate Strip Packing Machines

These machines use flat plates to form and seal strips. They are ideal for packaging fragile items like tablets because they provide uniform pressure during sealing.

2. Roller-Type Strip Packing Machines

Roller-type machines use rotating rollers to perform sealing operations. They are faster than flat plate machines but may not be suitable for highly fragile products due to potential pressure variations.

3. Thermoform Strip Packing Machines

These machines form cavities in a thermoplastic film using heat before filling and sealing them with another layer of material. They are commonly used for products requiring precise cavity dimensions.

4. Cold-Forming Strip Packing Machines

Cold-forming machines use aluminum-based laminates to create strips without applying heat. This method is particularly useful for heat-sensitive products like certain pharmaceuticals.

Advantages of Automatic Strip Packing Machines

The adoption of automatic strip packing machines offers numerous benefits for manufacturers:

1. Enhanced Efficiency

Automation significantly speeds up the packaging process compared to manual methods, enabling manufacturers to meet high production demands.

2. Improved Hygiene

Automatic machines minimize human contact with the product, reducing the risk of contamination—a critical factor in industries like pharmaceuticals and food processing.

3. Consistent Quality

These machines ensure uniform sealing quality across all strips, which is essential for maintaining product integrity during storage and transportation.

4. Reduced Material Wastage

With precise control over sealing and cutting operations, automatic strip packing machines minimize waste by optimizing material usage.

Applications of Automatic Strip Packing Machines

Automatic strip packing machines are versatile and find applications across various industries:

1. Pharmaceuticals

Used for packaging tablets, capsules, and other oral dosage forms in airtight strips that protect against moisture and contamination.

2. Food Industry

Commonly used for packing small food items like candies, chocolates, and spices in convenient single-use strips.

3. Consumer Goods

Ideal for packing items like tissues, small electronic components, and personal care products into compact strips.

Factors to Consider When Selecting an Automatic Strip Packing Machine

Choosing the right machine involves evaluating several factors:

- Product type and dimensions

- Production speed requirements

- Material compatibility (e.g., aluminum foil vs plastic film)

- Budget constraints

- Maintenance and operational complexity

- Regulatory compliance (e.g., GMP standards)

Future Trends in Automatic Strip Packing Technology

As technology evolves, automatic strip packing machines are becoming more sophisticated:

- Integration with IoT for real-time monitoring

- AI-driven quality control systems

- Use of sustainable materials to reduce environmental impact

- Compact designs for space-saving operations

- Customizable features for diverse industry needs

In conclusion, automatic strip packing machines represent a crucial advancement in modern packaging technology, offering unparalleled efficiency, hygiene, and quality assurance across various industries.